Professional

ASM EVO RS

ON DIVIDER

capacity (kg)

- 100

- 130

- 160

- 200

- 250

- 300

technical data

| Model | ASM RS 100 | ASM RS 130 | ASM RS 160 | ASM RS 200 | ASM RS 250 | ASM RS 300 |

| Dough capacity (min./max) *kg | 8/100 | 10/130 | 10/160 | 10/200 | 15/250 | 20/300 |

| Bowl volumelt | 155 | 205 | 260 | 285 | 380 | 470 |

| Motors power 1st /2nd speedKw | 2.9/5.3 | 3.6/6.3 | 4.6/7.4 | 4.6/7.4 | 5.4/8.6 | 6.8/12 |

| Height from bowl edgemmC | 1850 | 1820 | 1820 | 1820 | 1760 | 1720 |

| Total depthmmE | 1300 | 1320 | 1320 | 1500 | 1550 | 1600 |

| Total widthmmG | 1170 | 1220 | 1320 | 1320 | 1360 | 1410 |

| HeightmmA | 2740 | 2750 | 2930 | 2930 | 3080 | 3160 |

| Net weightkg | 990 | 1050 | 1220 | 1230 | 1250 | 1400 |

*: capacity based on the percentage of liquid/flour = 60%

All data are to be considered as nominal, MIXER srl reserves the right to make any changes to the product and/or technical specifications without notice.

standard features

• Painted steel structure, raised from the ground by 4 adjustable feet.

• Bowl, spiral, contrast column, closed guard and flour screen made of stainless steel.

• Two independent motors with 2 spiral and 2 bowl speed.

• Bowl thrust roller.

• Front control with 2 timers. Setting of work time with automatic shift from 1st to 2nd speed.

• Movement transmitted by pulleys and V-belts.

• Selector to reverse bowl motion.

• Impulse buttons to rotate bowl in order to remove dough (on machine and on lifter).

• Possibility to dump the bowl on divider (1,7 m approx.).

• Hydraulic lifting system.

• Dumping control with hold-to-run buttons.

on request

• Uprated tools speed (205rpm).

• Stainless steel structure with micro shot-peeing treatment.

• Computer with 7’’ touch-screen able to program 100 recipes and work in manual or automatic mode.

• Spiral with oversized bar.

• Uprated spiral motor.

• Contact probe for temperature measurement.

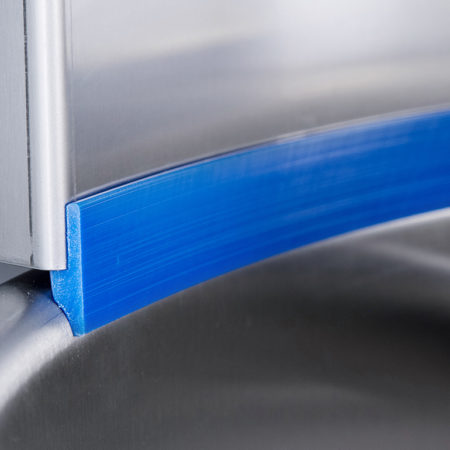

• Bowl lid made of stainless steel with airtight polyethylene rim.

• Lateral chute for very soft dough.

• Scarper for vertical side of bowl.

• Special voltage/frequency 230/50/3 – 220/60/3 – 380/60/3.

• Wooden crate packaging.

download pdf data sheet

For further information

contact us